Metal Finishing Services For Product Identification

IntelliCAM™ offers a variety of fabrication, laser cutting, and metal and plastic finishing processes that improve our value to customers. We have over 30 years of experience providing fabrication services to OEMs. Our capabilities include chemical etching, CNC routing, laser marking, Metalphoto® finishing services, rotary engraving, and screen printing.

Our Processes

Our range of metal finishing services for product identification at IntelliCAM™ allows you to choose the process that best meets your project needs. We will work with you to assess project parameters and requirements and recommend one of our processes to achieve your goals.

- Chemical Etching: Chemical etching creates a permanent design on aluminum and stainless steel surfaces. It is an excellent choice for industrial nameplates and product identification plates.

- CNC Routing: CNC routing creates a clean, 3D marking on metals and plastics. It is ideal for creating nameplates, serial plates, control panels, dials, and rules.

- Laser Cutting: Laser cutting is suitable for most metals, plastics, and polymers. Laser marking is very resistant to abrasion and wear. It is ideal for direct product marking and identification.

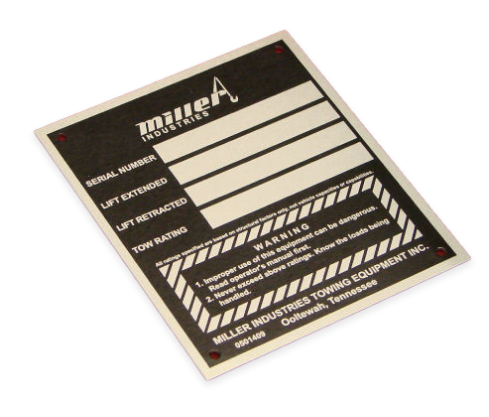

- Metalphoto®: Metalphoto® produces a permanent image on anodized aluminum. It is ideal for identification labels, serial plates, and nameplates.

- Rotary Engraving: Rotary engraving is a permanent and flexible solution for engraving metals, plastics, and polymers.

- Screen Printing: Screen printing can produce full-color labels, overlays, and identification plates for industrial equipment.

Explore Our Fabrication and Finishing Processes

IntelliCAM™ works with OEMs and industrial partners to create custom nameplates and industrial equipment identification products. We offer multiple Metalphoto® finishing services for marking products with barcodes, QR codes, serial numbers, VINs, and logos. Request a quote to find the right fabrication process for your project.